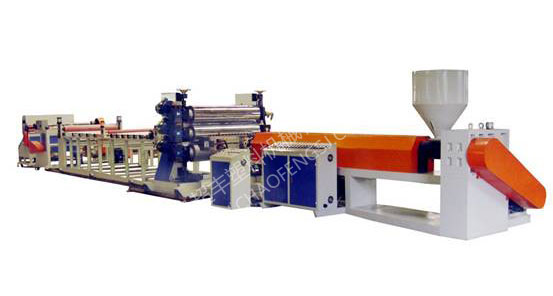

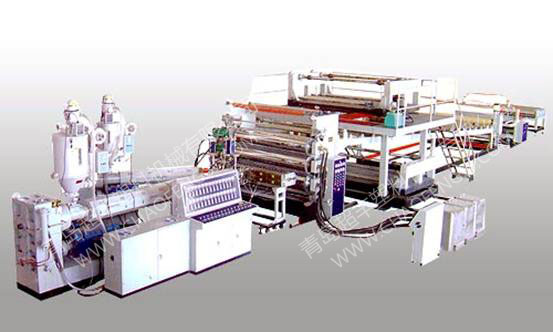

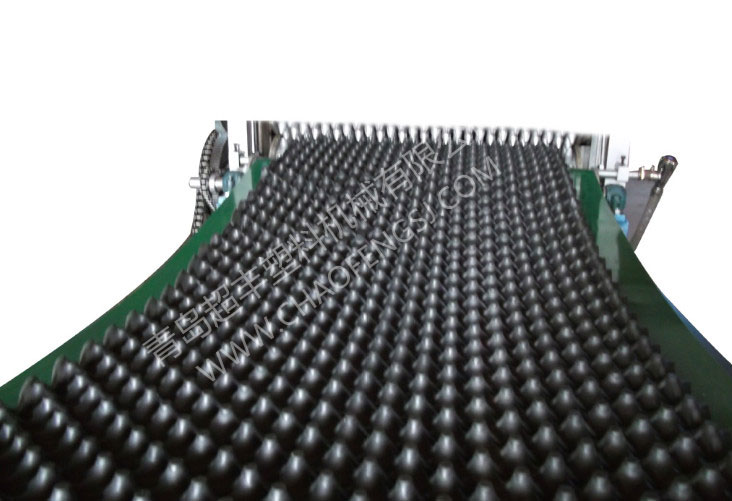

The roll forming machine consists of a feeding device, a heating device, a forming die roll set, a cooling device and a conveying device, which can continuously roll and form a regular and neat shape on any plastic sheet and coil. The molding machine can be flexibly customized according to customer's requirements. It is easy to replace and load and unload different types of mold rolls with different waveforms to make it more versatile. Reduce investment cost

Various plastic sheets or coils are softened by heating to roll out various waveforms required by the forming roller set. Its biggest feature is that it can be arbitrarily taken, and the required products can take one meter, two meters, three meters... Any length can be, can be continuously molded, which is an advantage that can not be replaced by injection molding machines and plastic machines.

Next:None